Blister tools

Presentation of your goods in blister packs

Blister packs, also known as face-shield packages, are nowadays almost everywhere: as the name implies, the lightweight deep-drawn packaging products offer optimal protection during transport, while simultaneously allowing the "view" inside the packaging and thus on the product.

Blister packs with a suspension device enable the presentation of the goods on the rack and facilitate the viewing of the products. Blisters are non toxic and we use them both for the consumer goods and at the food industry. The plastic packs are 100% recyclable and can be made of different plastics (according to customer requirements colored or transparent).

For the production of blisters, a forming tool is clamped in the thermoforming layer and the heated plastic film is drawn down by means of a vacuum. This process is called thermoforming.

TOOL, MOLD AND FIXTURE CONSTRUCTION • Made in Germany

Keep it simple and consult with us now!

We are happy to assist you with the technical design of your thermoforming tools.

From the very beginning or also in later process phases.

Tel.: +49 (0)7261 - 5849

Manufacture of molds

A good blister production depends decisively on the precise construction of the mold as well as on its well planed design: Thanks to many years of experience, we are able to develop the right blisters for your products. Whilst planning a blister we are focusing on their handling during the packaging process as well as the requirements in the subsequent handling by the sales department and the final customer.

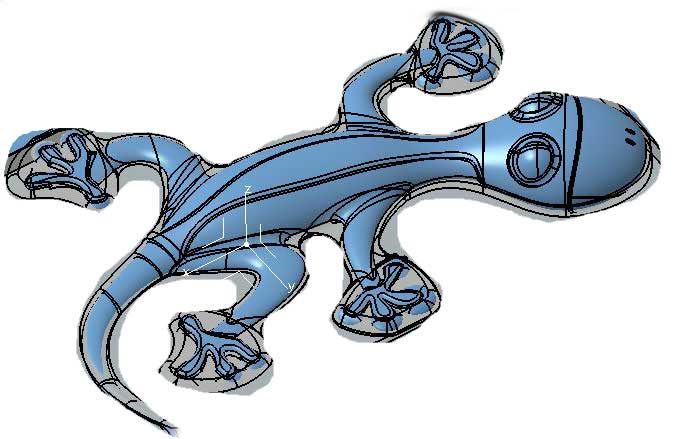

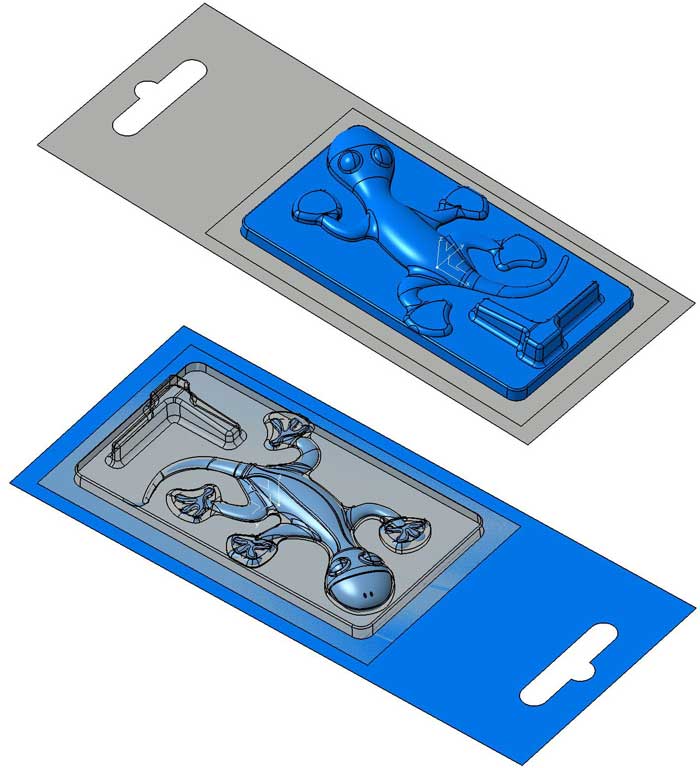

1. Packaging design / packaging construction

Upon priorconsultation over the packaging concept and the component feed, we draw up a depiction of the blister packaging in order to visualize your final product.

The rendered data could be available as a .pdf-, .dxf-, 3D-, or stp.-format.

Besides the classic packaging blisters on blister cards with Euro-standard holes on hooks we offer other options e.g. :

• Stand blisters by undercut

• Blister film - foil

• Folding blisters

• Double card blister

• and many more.

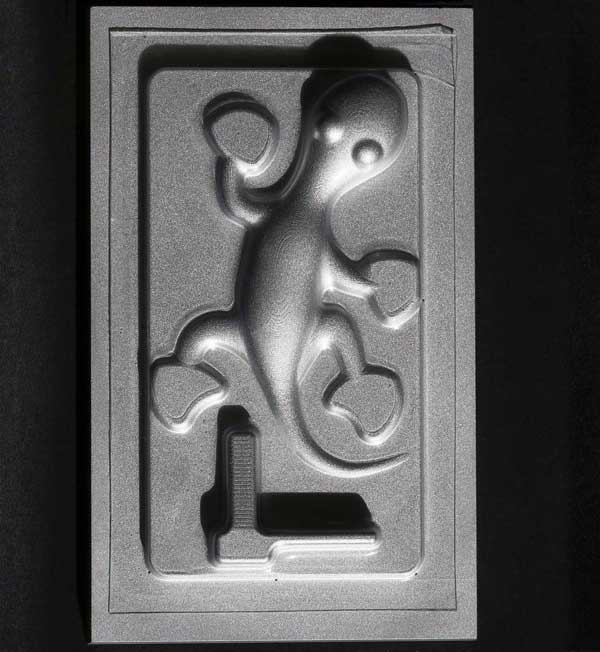

2. Prototype / sample

As soon as the packaging concept is approved, we will create a sample model made of aluminum so as to thermoform your first test blisters: We can provide you with small batches of up to 200 pieces which you can use for demonstration purpose as well as packaging and transporting tests.

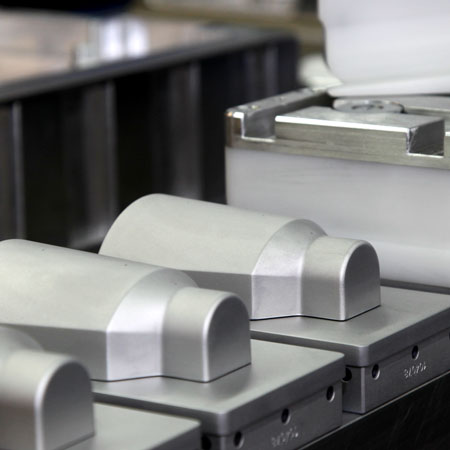

3. Series tool

After the sample packaging is released, we will create the serial tool according to your blister machine.

Consisting of molds, pruning, sealing and all necessary transfer units.

We consider ourselves an expert for all common vacuum, compressed air deep drawing machines of the following brands:

• Illig (HSA Serien) • Zahoransky • Hamer • Koch • ALMA • Kiefel • Mulivac-Maschinen.

Contact us for a personal offer!

4. Tool maintenance / tool overhauling

In order to ensure a consistent high quality packaging, we would be very glad to take over the maintenance and repair of your tools.

We offer you:

• Repairing areas of excessive abrasion by grinding or re-milling

• Bead blasting of your blister tools

• Restoration of the planarity of individual tool components

• In the case of damage molds, complete replacement is possible: We archive all construction data.

Portfolio Schubert GmbH Sinsheim

Our many years of experience make us skilled at designing even the most demanding blister tools.

See our portfolio