Construction / Engineering

s

Tools for plastic processing companies as well as for end users from various branches of industry

Thermoforming tools are indispensable tools in the manufacturing industry, especially in the thermoforming sector. They are used for the production of plastic products such as food packaging, medical devices and car parts. The production of thermoforming tools requires a lot of expertise, precision and experience..

Schubert GmbH has many years of experience in the design and manufacture of thermoforming and blister tools. We skilfully apply this valuable pool of experience in the development and manufacture of our tools, which enables us to support you effectively - from the very first moment of your initial enquiry. Regardless of whether you already have a firm layout of your tool at the time of contacting us or whether you are still completely uncertain in its requirements and final design!

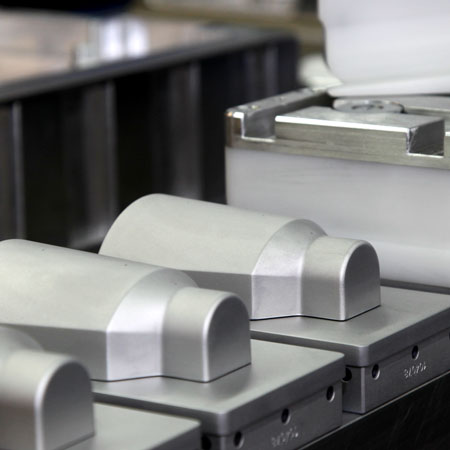

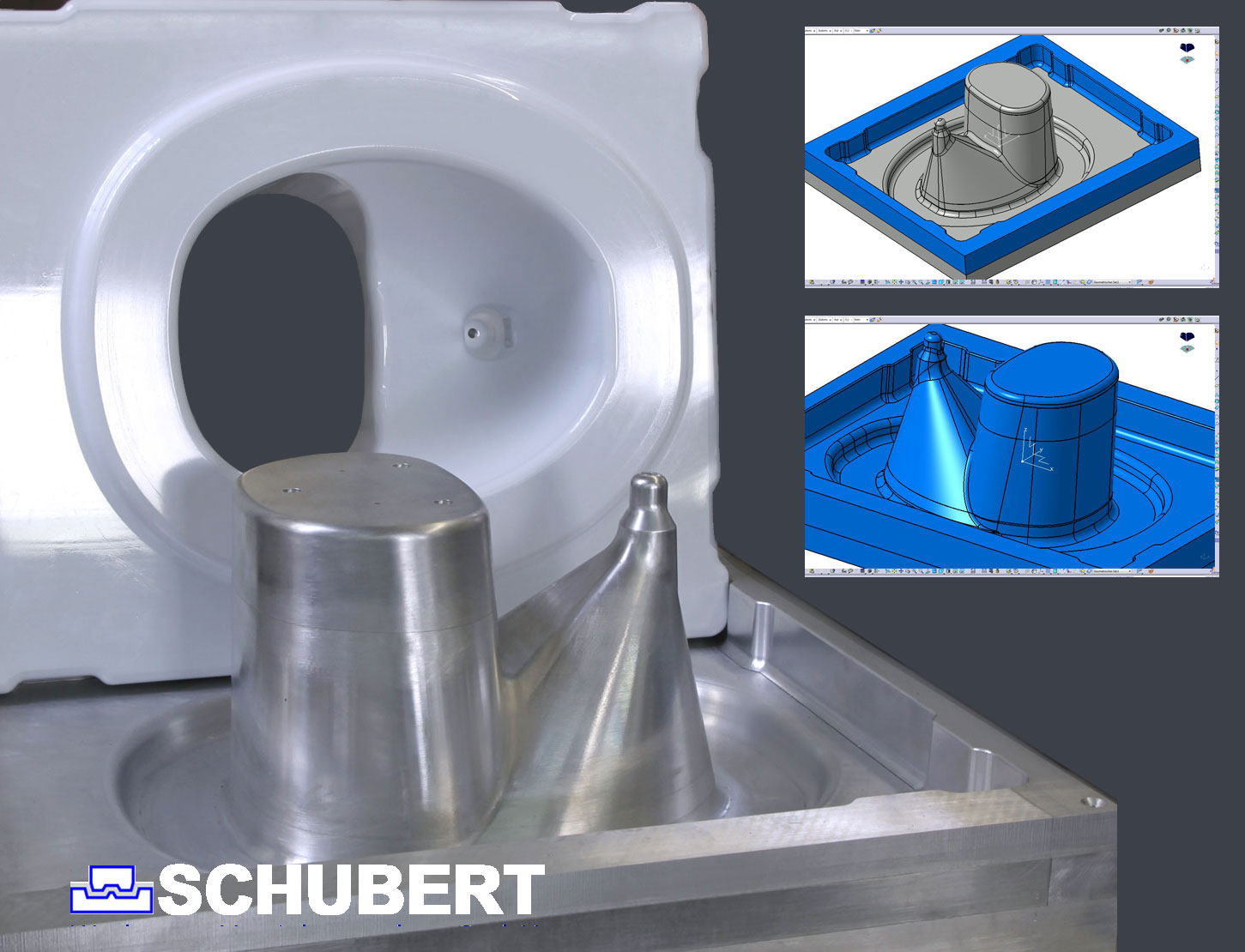

The tool design is crucial to the subsequent success of the product, as it determines the quality and accuracy of the final product. After the initial design has been completed, a tool sample is created. Here, a model of the future tool is simulated in 3D software; in addition, we often also create additional mould models from aluminium. In doing so, we approach the final tool design step by step. After completion of this process and approval of the prototype, the actual tool is made out of metal, steel or . For this purpose, we use high-quality materials such as aluminium or steel which we process in our CNC machinery centre to manufacture the desired form. Obviously always individually adapted to the requirements of your company.

Many years of experience in the design & layout of mold tools

In order to ensure the quality and efficiency of the deep drawing process, a number of aspects must be taken into consideration during the development of a deep drawing tool:

- The selection of the appropriate material for the tool, which should have high wear resistance, hardness and toughness, as well as good thermal conductivity and corrosion resistance.

- The design of the tool geometry, which takes into account the shape and size of the product to be deep-drawn, and is responsible for the optimum thermoforming properties of the material in terms of distortion and extrusion behavior.

- The surface finishing of the tool: Depending on the project, it may be necessary to polish tool surfaces or roughen them by means of bead blasting.

- The adaptation of the tool to the thermoforming machine, which ensures the fixation, alignment and clamping of the tool. The tool should also enable easy handling and quick change.

- The maintenance and care of the tool, which includes regular cleaning, lubrication, inspection and repair of the tool.

Three modern design workstations with Catia V5

With our 3 modern construction workstations with Catia V5, Schubert GmbH can provide you with the first rough layouts through to finished construction drawings: pdf and dxf drawings for 2D data or 3D data in *.stp, *.igs, and *.3dxml data. Due to the flexibility of a small company, we can provide you with these data and layouts within a comparatively short time.

TOOL, MOLD AND FIXTURE CONSTRUCTION • Made in Germany

Keep it simple and consult with us now!

We are happy to assist you with the technical design of your thermoforming tools.

From the very beginning or also in later process phases.

Tel.: +49 (0)7261 - 5849

Complete tray constructions including wall thickness

We create final tray designs for you, including wall thickness, according to which you can check the later tray for component position, stacking height, automation environment and transport dimensions and adapt it with regard to the required ports.

Again, as developers of a proper tray tool, we have to pay attention to several aspects to ensure the quality and efficiency of the tray designs. Important are:

- The selection of the appropriate plastic material for the tray, which should have good thermoformability, strength and durability, as well as a suitable colour and surface for the product.

- The design of the tray geometry, which takes into account the shape and size of the product to be packaged, as well as the optimal positioning and fixing of the products in the tray.

- The choice of the wall thickness of the tray, which should be as even and as thin as possible to save material and costs. Yet the wall thickness should also be thick enough to withst mechanical impact (avoiding sink marks and deformation).

- The adaptation of the tool to the thermoforming machine.

Previsualisation in 3D

We are also happy to offer you presentations of your design in which the complete scope of the later tray can be seen through 3-D images. We only create layouts that can be realised later in terms of production technology - both from the point of view of toolmaking and from the point of view of thermoforming. In the later course, we are therefore also at your disposal for the creation of the first samples as well as the series tool.

Thanks to our many years of experience and cooperation with thermoforming companies, we can introduce you to competent thermoforming companies that can supply you with the finished thermoformed product.

Construction of a dry toilet. With thermoformed patterns made of ABS (acrylonitrile butadiene styrene).

Portfolio Schubert GmbH Sinsheim

Our many years of experience make us skilled at designing even the most demanding blister tools.

See our portfolio