Cardboard Blisters

Presenting products with maximum appeal and in an eco-friendly way: With sustainable cardboard blisters

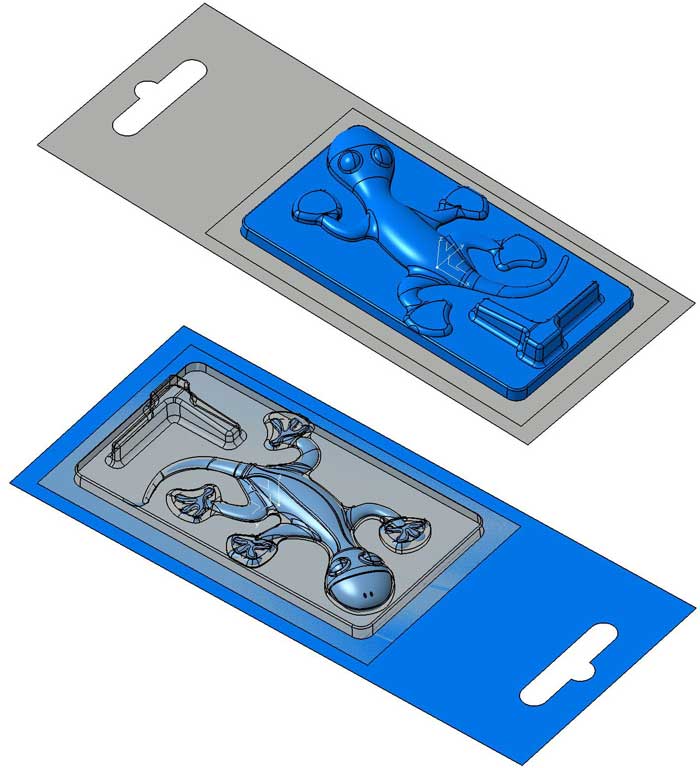

Full cardboard blister packaging can be made from 100% recycled or renewable cardboard. The cardboard is shaped into the desired form with the help of tools and then loaded with the products.

Solid cardboard blisters made from 100% recycled or renewable cardboard

The environmentally friendly alternative to traditional blister packaging, made from renewable raw material, makes it easy for your customer to recycle. In addition, full cardboard blisters allow artwork to attract your customer's attention at the PoS while communicating an environmentally friendly image..

- Best possible brand visibility of the product due to large advertising space

- Environmentally friendly image combined with sustainability

- Attractive product presentation

- Improved handling at the POS, especially for smaller products

- Effective protection against theft

☎ +49 (0)7261 - 5849

✉ info@schubert-sinsheim.de

Production of tools for solid cardboard blisters and conventional blisters

Although the appearance of a full carton blister may hardly differ from that of a conventional blister packaging, there are some subtleties to be taken into account during mould production in order to design and manufacture the appropriate moulds. Here, too, experience plays a weighty role. Some differences are:

- A blister pack consists of a plastic film that is formed into a shape and a cardboard card that serves as the back. The plastic film is loaded with the product and sealed with the cardboard card. A blister pack can be made of different plastic materials such as PET, PVC or PS.

- A full carton blister consists solely of cardboard that is formed into a shape and contains the product. The cardboard is glued or compressed at the edges to seal the package. A full carton blister can be made of recycled or renewable cardboard.

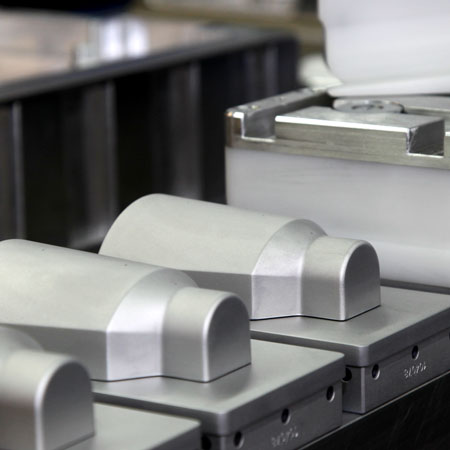

- The forming tools for blister packs must be made of heat- and corrosion-resistant material such as aluminum. The foil is heated and deep-drawn over the mold. The surface finish must be chosen in accordance with the product, the machine and the material to be processed.

- The forming tools for solid carton blisters usually consist of a variety of components, which are made of aluminum, steel or brass depending on the loads and movement sequences. To support the bending movement of the carton, tool components can also be provided with anti-adhesive coatings.

In-house: engineering / design, layout creation & own toolmaking guarantee rapid production workflows and well-thought-out solutions

☎ (07261) 5849

Schubert GmbH manufactures tools for all types of machines.

We will be happy to accompany you from the first geometric design to the sample production of a cardboard packaging to the perfect series tool.

Thanks to our strong presence in the packaging market, we have access to partners in the field of carton printing and, if required, can call on proven production procedures for the manufacture of the final packaging.

Portfolio Schubert GmbH Sinsheim

Our many years of experience make us skilled at designing even the most demanding blister tools.

See our portfolio